Intrastack, part of Saint Gobain’s Off-Site Solutions division, has developed and launched its panelised steel-frame system for the UK’s building sector.

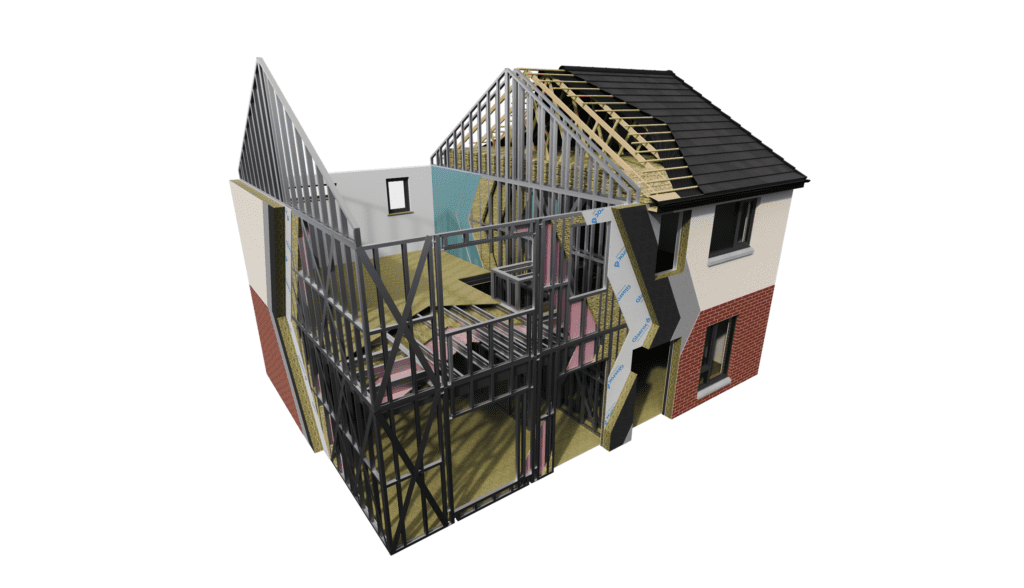

The new, panelised, light gauge steel frame solution has been designed to help contractors and housebuilders deliver multi-storey, multi-occupancy residential and commercial projects. Intrastack can provide a full, steel-frame building structure of up to 12 storeys high, delivering greater efficiency and reducing the need for extensive on-site construction works.

Intrastack’s offering provides the full load-bearing structure in light gauge steel, which has an NHBC Stage 1 certification from the Steel in Construction Institute (SCI). The steel frame is available with either LGSF cassette mid-floors and roofs or composite concrete floors and roofs. Following comprehensive fire resistance and acoustics testing, the steel frame systems will provide 120 minutes of fire performance.

The new panelised system is highly versatile and can be adapted to suit any standard or complex requirements of a build. Whether you’re working on a hotel, apartments, student or low-rise housing, Intrastack will ensure simplicity and safety, while increasing the speed of construction by up to 50 per cent in comparison to traditional methods.

Each panel is manufactured and assembled at Saint-Gobain Off-Site Solution’s 15+ acre, multi-disciplined Modern Methods of Construction (MMC) facility in the North-West of England.

Andy Higson, Business Director at Intrastack, said: “Following extensive market research, it was clear that clients, developers, and contractors required clarity around four key factors when considering a new system. Firstly, the solution must perform well and be tested, manufactured and assembled in a controlled factory setting.

“Secondly, accurate information on exact tolerances must be communicated; thirdly, the system must be quick to erect and integral in speeding up the wider construction programme.

Finally, costs must be accurate and clear. By working closely with our existing customers across multiple schemes, it is clear that we’ve delivered on market requirements and will continue to retain our keen focus on innovation and developing further MMC solutions.

“We work closely with our customers at the earliest stages of a project, we support concept ideation, detailed system design, installation, and ongoing interaction with associated follow-on trades.”

If you have a current or upcoming steel frame UK project you’d like to discuss with us, get in touch by emailing .

If you’re an installer and interested in joining our national network, please contact us to find out more. For regular updates, follow us on LinkedIn @Intrastack.

Article originally appeared in Specification Magazine, April 2022: